SCROLL & LEARN MORE

SCROLL & LEARN MORE

For a structure to have a top-notch performance with maximum strength and durability, it must include reinforcement bars.

Reinforcement bars are steel bars or wires used in reinforced concrete to strengthen the concrete and keep it in an exact position. The detailer usually specifies the number of bars, bends, and positions, but the ironworkers generally make the central arrangement of those reinforcement bars.

With proper methods of placing reinforcement bars in concrete, the ironworkers can ensure that the structure performs impeccably under tension.

Today’s article will talk about the 6 methods and standard procedures used when placing reinforcement bars in concrete.

Before doing any reinforcement work, we need to ensure that the steel bars used for reinforcement are completely clean and free from dust, rust, oil, paint coats, or any other coating that might jeopardize the bond strength.

The steel bars should be safely stored to avoid corrosion, distortion, and deterioration.

Also, it’s essential to apply a lubricant before assembling the reinforcement bars in case there is rust that should be removed.

If you want to place the reinforcing steel perfectly, it’s necessary to obtain the exact amount of concrete cover.

The concrete cover is the specific amount of concrete that goes between the reinforcing steel and the top surface of the concrete member. The requirements for the concrete cover are often described in the project specifications. Still, as a good rule of thumb, engineers use the following specifications:

– For concrete exposed to earth: 3 inches (7.6 cm).

– For concrete exposed to weather or earth: 2 inches (5 cm).

– For concrete not exposed to both: ¾ inches (1.9 cm).

The main role of the concrete cover is to protect the reinforcing steel from corrosion.

The second important role of the concrete cover is to ensure that the steel is bonded to the concrete well enough that it develops an unbreakable strength.

The reinforcement bars should be assembled in a specific way.

First, they need to be bent accurately according to the shape and size described in the drawing. It’s common practice for the bars to be at full length when assembling. However, sometimes there can be done some cutting if needed.

Overlapping of the reinforcement bars is a precise work that should be directed by the engineer, who can instruct how they should touch together and how to be kept apart with concrete between them.

The design of any structure directly depends on positioning the steel reinforcement bars in the right place – as shown in the initial drawings. Any incorrect steel positioning (even by 1 cm) can cause serious concrete failures.

The reinforcement bars that are crossing each other should be tied together extra tight at the intersections with annealed steel wire. This is important, so the skeleton of the reinforcement doesn’t get displaced when concrete is deposited.

Often the reinforcement bars are not tied at every intersection, and every fourth or fifth is usually sufficient. It’s important to note here that the ends of the wires should be kept away from the surface of the concrete due to corrosion.

Track welding in crossing bars is not usually recommended because it significantly reduces the cross-section of the bars. However, it can be permitted if the engineer approves it.

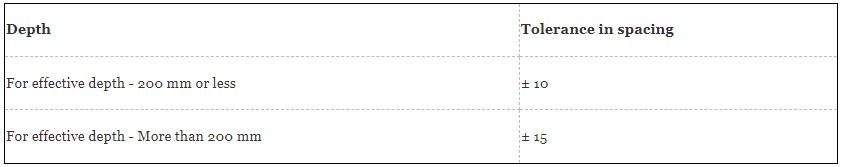

Ideally, the reinforcement bars should be placed at the exact specified position, but there always will be some small variations. And if you wonder how small variations (or tolerance), you can see in the table below:

When there is a need for the reinforcement bars to be bent at construction joints (and later bend pack into the initial position), the ironworkers should ensure that the radius of the bend is always less than 4 times the bar diameter.

The ironworkers should also be very careful when bending the bars back into their original position because they might damage the concrete around the bars.

Any well-performing structure relies on its reinforcement bars for extra strength and durability.

However, placing reinforcement bars in concrete is not an easy task and needs to be executed with great precision by the detailers, ironworkers, and engineers.

Today, we’ve discussed some of the key rebar installation methods that we at Breon incorporate into our design to ensure top-notch rebar schedules and smooth rebar installation.

Contact our professionals today if you need assistance with rebar schedules for your projects. We will respond to your trust with quality.

References:

https://theconstructor.org/practical-guide/place-reinforcement-bars-concrete/45481/

https://www.constructioncost.co/methods-for-reinforcing-steel-placement.html

https://www.concreteconstruction.net/how-to/construction/placing-reinforcing-steel_o